Spiral Wound Gaskets: Your Ultimate Sealing Solution for Demanding Applications

When dealing with high pressures, extreme temperatures, and critical fluids, it is imperative to choose the best seal. Spiral wound gaskets excel in this regard, and we specialize in this complex, precision-engineered sealing technology. Unlike companies offering spiral wound gaskets among a wide array of products, we specialize in spiral wound gaskets.

Spiral Wound Gasket : What You Need to Know ?

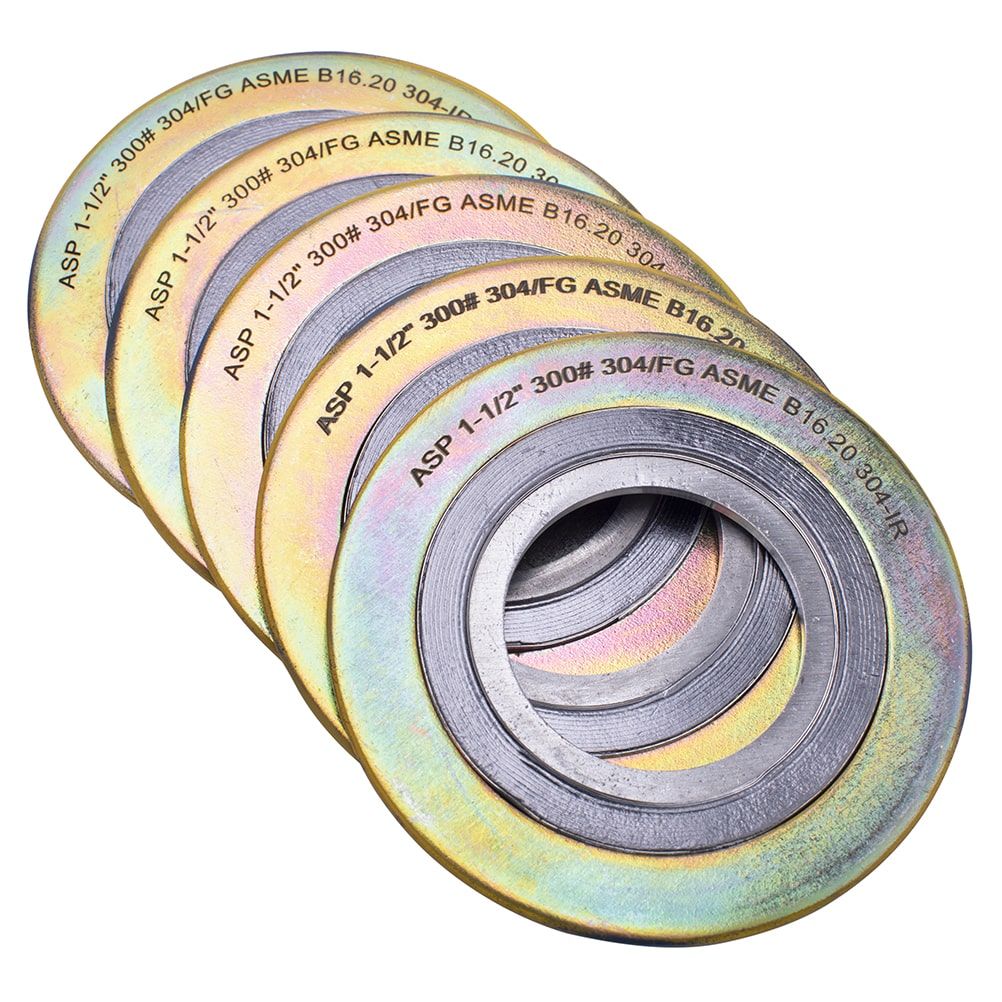

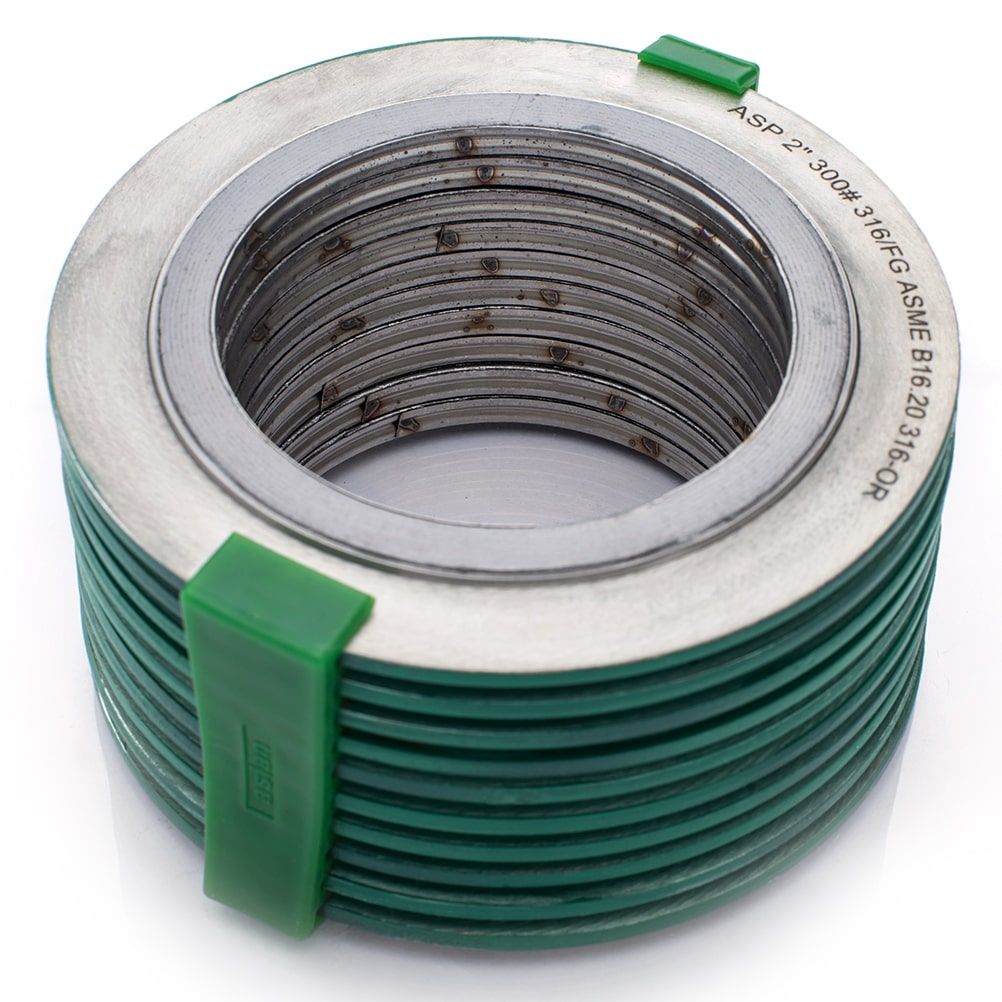

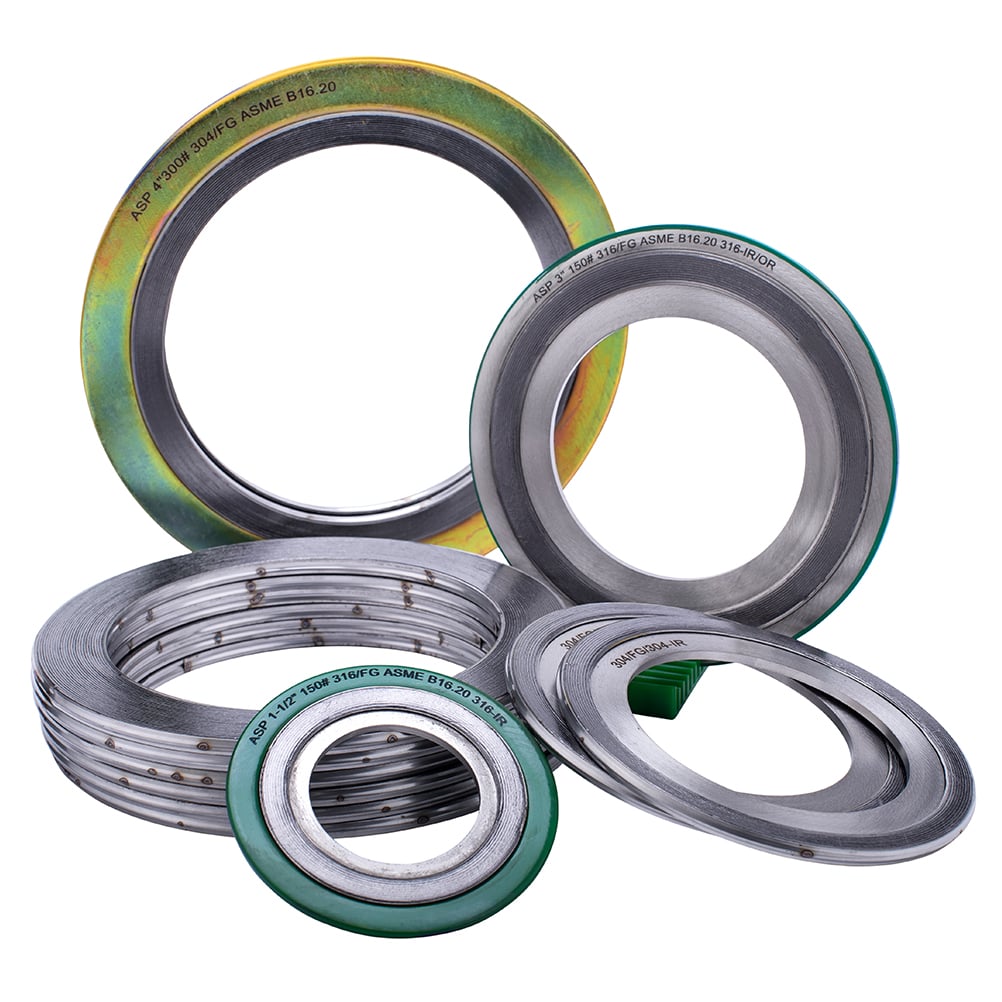

Spiral wound gaskets are a premium, semi-metallic sealing solution. They consist of:

Metallic Winding Strip: Forms the core; common materials include various grades of stainless steel for strength and corrosion resistance.

Soft Filler Material: Graphite, PTFE, or others are used for compressibility and to enhance the seal between the gasket and flange faces.

Inner and Outer Rings (Optional): Add stability, center the gasket, and act as compression limiters.

Benefits of Spiral Wound Gaskets

Extreme Resilience: Handle high temperatures, pressures, and fluctuating loads.

Chemical Compatibility: Diverse materials to choose from for compatibility with various fluids.

Fire Safety: Selected configurations can achieve fire-safe ratings.

Reduced Emissions: Help minimize fugitive emissions for regulatory compliance.

Where Spiral Wound Gaskets Shine ?

Pipelines: Oil & gas, chemical processing, water/wastewater transport.

Flanges, Vessels, and Valves: Critical joints in refineries, power plants, and more.

Heat Exchangers: Maintains separation between fluids while handling temperature extremes.

Specialty Applications: Aerospace, nuclear, and other high-performance industries.

Spiral Wound Gasket Standards

At Asian Sealing Products, we understand gaskets’ critical role in ensuring safe and reliable connections. Our spiral wound gaskets are manufactured to meet the highest industry standards.

Built to Last:

Dimensional Accuracy: Our gaskets adhere to strict dimensional tolerances outlined in global standards like ASME B16.20 to suit ASME B16.5, ASME B16.47 Series A & B, API 605, MSS SP44 Flanges, EN 1514-2 to suit EN1092 Flange, BS 3381 to suit BS 1560 Flange, JIS B2404 to suit JIS B2220, JIS B2240 Flanges, and BS 4865-2 to suit BS 4504 Flange, Gaskets to suit BS 10, DIN flanges, etc. are compatible with various flange specifications. This ensures a perfect fit within your flange connections, preventing leaks and blowouts.

Material Performance: We use high-quality materials for the metal winding and the filler, ensuring compatibility with various fluids and temperatures.

Pressure Rating: Our gaskets are available in various thicknesses to meet the specific pressure requirements of your application.

The ASME B16.20 standard governs the dimensions of spiral wound gaskets for use with flanges conforming to other ASME B16 standards (like B16.5 and B16.47). This ensures proper fit and performance.

Why Choose Us for Your Spiral Wound Gasket Needs?

- Expertise Beyond the Basics: We don’t just sell gaskets; we understand your applications. Our team uses industry knowledge to guide you toward the optimal spiral wound gasket configuration, ensuring reliable, leak-free performance in even the harshest environments.

- Customization is Key: Don’t force your process to fit the gasket. We offer various material choices, winding densities, and dimensions to ensure a perfect fit for your flange specifications and operational parameters.

- Quality that Goes the Distance: Our spiral wound gaskets are manufactured with uncompromising precision, utilizing best-in-class fillers, winding metals, and rigorous in-process quality control. The result? Gaskets that deliver long-term reliability.

- Industry-Specific Solutions: From petrochemical plants to power generation, we’ve tackled the unique sealing challenges of various sectors. Bring us your application, and we’ll bring you the right spiral wound gasket solution.

- The Competitive Edge: We understand that value matters. That’s why we strive to deliver the best combination of sealing performance, customization, and competitive pricing.

We’re More than Just a Supplier; We’re Your Sealing Partner

Don’t see your specific situation reflected here? Contact us and be surprised! Our technical experts are always available to discuss your unique application challenges and help you find the perfect spiral wound gasket solution. From one-off replacement needs to large-volume orders, we’re committed to exceeding your expectations.

Experience the Asian Sealing Products’ Difference

Ready to discover a better way to source spiral wound gaskets? Browse our selection of types and standard sizes or Contact us today for a personalized consultation and experience the superior quality, expert support, and value we bring to every order.

Let’s seal the deal!