Welcome to Asian Sealing Products, the legend of industrial sealing excellence—our PTFE gaskets. In precision engineering, polytetrafluoroethylene, more commonly identified as PTFE, unequivocally takes the lead in sealing technology. This product page sets forth a comprehensive exploration, uncovering the importance of PTFE gaskets.

Applications

Our PTFE gaskets are known for their extravagance, making them essential in various industries. Their outstanding performance shines in major environments like pharmaceuticals, petrochemicals, food and beverage processing, and aerospace. PTFE gaskets protect equipment and streamline operational processes in these sectors. The extraordinary sealing capabilities of PTFE gaskets prevent leakages and contribute significantly to operational efficiency. Their reliability spans various sectors, making PTFE gaskets indispensable for creating secure seals and optimizing performance.

- Pharmaceutical Excellence: Flourishing within the landscapes of pharmaceutical environments, PTFE gaskets guarantee proper sealing and safeguarding of equipment.

- Petrochemical Resilience: In the rigorous conditions of petrochemical settings, PTFE gaskets are essential, offering steadfast sealing solutions.

- Food and Beverage Prowess: Due to rising food and beverage processing demands, these gaskets are pivotal in maintaining impeccable hygienic conditions and optimizing operational processes.

- Aerospace Precision: Integrated into aerospace machinery, PTFE gaskets play a pivotal role, providing reliable seals to endure and overcome the distinctive challenges of aerospace environments.

Specifications

Precision is of utmost importance in the process of industrial sealing, and PTFE gaskets meticulously adhere to stringent specifications. From precise dimensions and pressure ratings to exceptional temperature resistance and

chemical compatibility, this section offers a comprehensive exploration of the technical intricacies ensuring the reliability and efficacy of PTFE gaskets.

Materials

The carefully selected materials employed in their construction are at the core of PTFE gaskets. Immerse yourself deep in material science as we dive into the eco-friendly, durable elements that collectively contribute to the exceptional properties of PTFE gaskets. Gain insights into how the meticulous choice of materials enhances chemical resistance, thermal stability, and overall functionality, setting these gaskets apart in the competitive landscape of industrial applications.

Asian Sealing Products PTFE gaskets represent more than just sealing solutions; they are committed to precision, innovation, and reliability. Whether facing extreme temperatures, high pressures, or corrosive environments, PTFE gaskets shine in adversity. As you navigate the complexities of industrial operations, consider these gaskets as your steadfast allies, elevating your processes to new standards of efficiency and resilience. Connect with us to explore how PTFE gaskets can redefine excellence in your industrial applications.

Types

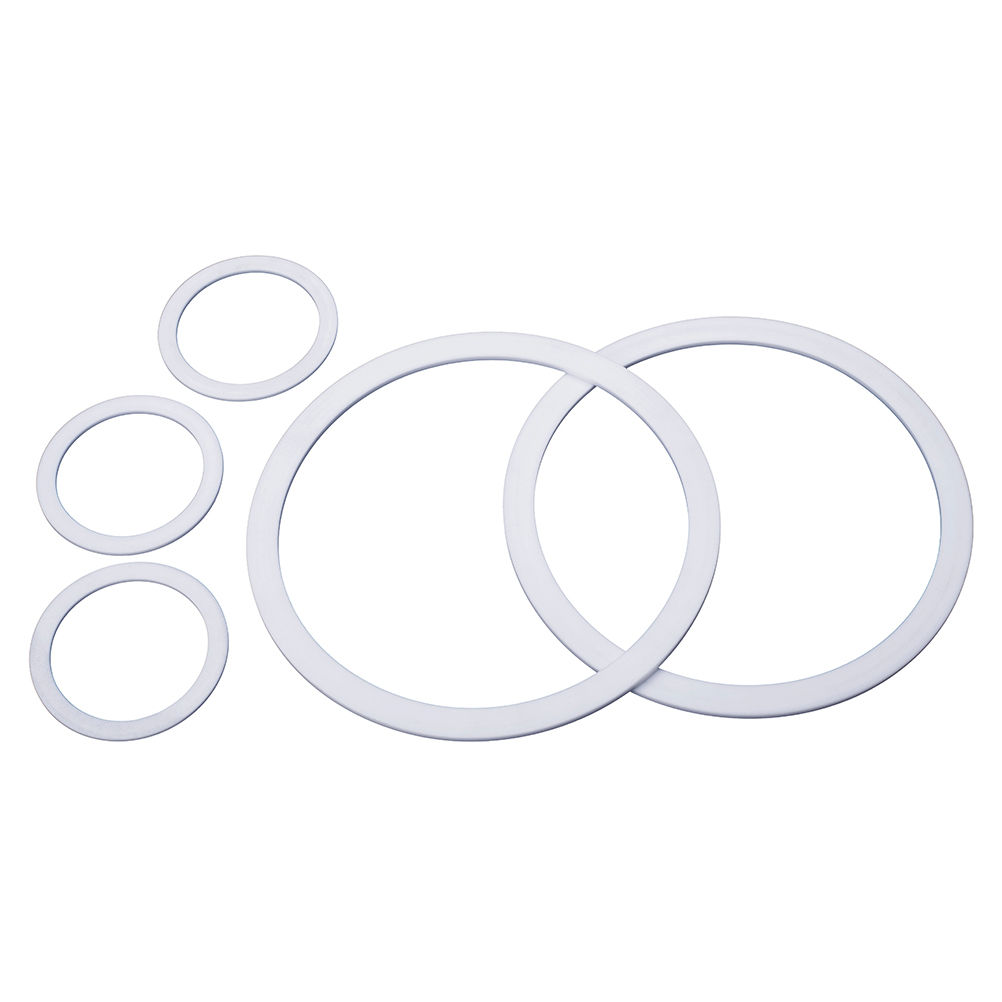

Look into the expansive spectrum of our PTFE gaskets, precision-engineered to address specific industrial requirements and various applications. Each type is designed precisely and tailored to meet distinct requirements within various sectors. Delve into the intricacies of these PTFE gasket types, each serving a unique purpose:

- Raised-Face Gaskets:

These gaskets are engineered with precision and feature a raised surface for optimized sealing in specific industrial applications. Their design ensures enhanced pressure resistance and sealing efficiency. - Full-Face Gaskets:

Tailored for comprehensive sealing, full-face gaskets provide complete coverage, making them ideal for applications requiring a thorough and secure seal. They excel in environments where containment is crucial. - Customized Gasket Type: We offer a wide range of customized gaskets that are manufactured using superior quality raw material. These gaskets are available in different sizes, shapes and thicknesses to meet the varied requirements of our customers. Our customized gaskets are used extensively in industrial applications are known for their durability, high performance and low maintenance.

- Envelope Gaskets:

Discover the versatility inherent in envelope gaskets, where a robust core material finds protection within a PTFE envelope. This innovative design not only harnesses the advantages of PTFE but also augments strength, rendering it apt for a diverse range of demanding applications.

Every variation of PTFE gasket boasts distinctive characteristics and applications, collectively enhancing the overall versatility of PTFE gaskets. Develop a comprehensive understanding to make informed decisions and choose the most suitable gasket for your industrial needs.